Product Consultation

Your email address will not be published. Required fields are marked *

Do solar wall lights require special maintenance?

Feb 28,2026Are the Lights from Sensor Night Light Harmful to the Eyes?

Feb 20,2026Where are Sensor Night Lights Suitable?

Feb 13,2026How long is a “normal” runtime for an LED flashlight?

Feb 06,2026Where are solar wall lights suitable for installation? Can they be used indoors?

Jan 30,2026Can solar wall lights be installed indoors or under eaves?

Jan 23,2026Which Nightlight Color is Best for Sleep? A Guide to Choosing Sleep-Aid Light

Jan 16,2026What is the working principle of a Solar Working Lamps?

Jan 09,2026What is an LED Night Light?

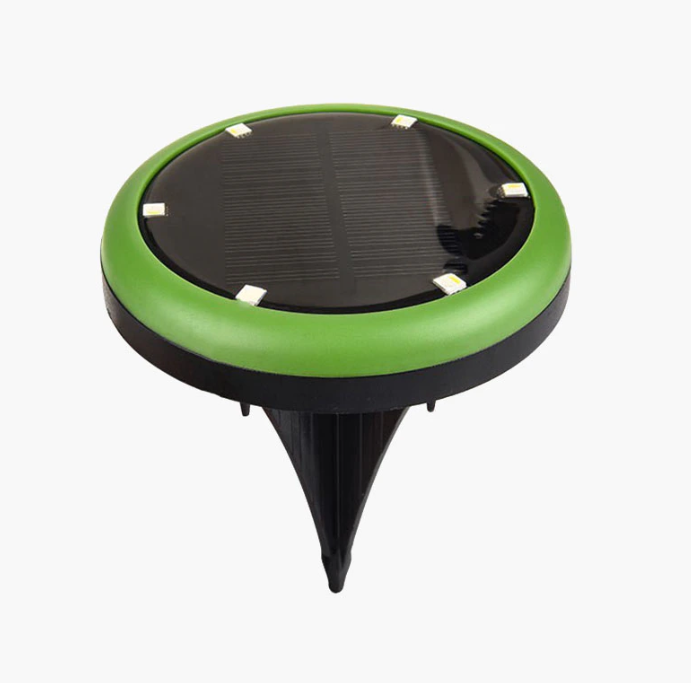

Jan 02,2026What's the difference between monocrystalline silicon and polycrystalline silicon Solar underground lights?

Dec 26,2025What is the core energy conversion component of a solar wall light?

Dec 19,2025What are the main application scenarios designed for LED aluminum flashlights?

Dec 12,2025When purchasing Solar underground lights, many customers are often confused by the terms "monocrystalline silicon" and "polycrystalline silicon" on the specifications. As a professional manufacturer of Solar underground lights, we understand that the choice of photovoltaic panel directly determines the charging efficiency and lifespan of the light fixture.

This is the most fundamental difference between the two.

Monocrystalline silicon solar panels: Made of high-purity monocrystalline silicon rods, with a simple molecular structure, their photoelectric conversion efficiency is currently the highest, typically between 18% and 24%. This means that, for the same size, monocrystalline silicon Solar underground lights can generate more current.

Polycrystalline silicon solar panels: Composed of multiple crystals arranged together, their conversion efficiency is slightly lower, generally around 15% to 18%.

Solar underground lights are usually installed on the ground and are sometimes obstructed by surrounding landscaping plants or buildings.

Monocrystalline silicon: Offers superior low-light response. Even on cloudy or rainy days, or in the early morning or late afternoon when sunlight is insufficient, monocrystalline silicon panels can still charge weakly.

Polycrystalline silicon: Requires relatively higher light intensity; charging performance decreases significantly under cloudy conditions.

Since solar-powered in-ground lights are outdoor landscape lighting, they are exposed to wind and sun year-round.

Monocrystalline silicon: Mature encapsulation technology, stable physical properties, and a lifespan generally exceeding 20 years, with a lower annual degradation rate.

Polycrystalline silicon: While meeting basic usage requirements, its performance degradation rate is often slightly faster than monocrystalline silicon in extreme high or low temperatures.

Appearance: Monocrystalline silicon is typically deep black or near black with a uniform color; polycrystalline silicon is blue with crystal patterns resembling ice flowers.

Polycrystalline silicon has a simpler manufacturing process and lower energy consumption, making it more cost-effective; while monocrystalline silicon solar-powered in-ground lights have a more complex manufacturing process, resulting in a slightly higher cost.

When choosing Solar underground lights for your high-end landscape projects, we recommend:

For long battery life and high brightness: Monocrystalline silicon is the first choice. Especially in northern regions with short winter days, the high conversion efficiency ensures the lights stay on all night.

For large-area lighting with a limited budget: If it's a large-area installation such as in parks or greenways, and the local sunshine is abundant, polycrystalline silicon solar in-ground lights offer excellent cost-effectiveness.

As a solution provider dedicated to high-quality outdoor lighting, every solar in-ground light we produce uses Grade A photovoltaic chips to ensure that every kilowatt-hour of sunlight is used effectively.

Your email address will not be published. Required fields are marked *

Copyright ? Conbo Electronics Co., Ltd. All right reseved. Custom Led Lights Manufacturers Wholesale Outdoor Light Fixtures Factory